Steel chemical treatment

Steel parts - will have certain activity in the medium heat, heat preservation, medium to one or more of the following elements of steel surface, infiltration by changing its chemical composition, microstructure and properties of heat treatment process called chemical treatment.

[the]] : (1) the basic process in a certain temperature decomposition: active media, through chemical decomposition of the workpiece, can penetrate into active atoms, (2) : workpiece surface activity, and atomic absorption material into the gap with grid formation elements or compounds, 3 the atomic absorption diffusion: from the surface to the heart of diffusion gradually formed, and a certain depth.

[objective] : (1) improve carbonitriding layer hardness &abrasion resistance (such as infiltration carbon, nitrogen, boron, vanadium, niobium, chromium, silicon, etc.), (2) improve parts contact fatigue strength and improve the ability to scratch resistant (such as sulfur, nitrogen, etc.) infiltration, (3) improve parts anti-oxidation, high temperature resistant properties (such as aluminum, chromium, nickel infiltration); etc. 4 improve parts anti corrosion (such as infiltration silicon, chromium, nitrogen, etc.).

[the]] : carburizing commonly used types, nitrogen, carbon and nitrogen of total nitrogen, carbon leachate

A, carburizing

- carburizing is part of the carbon atom is in medium heat, heat preservation, make carbon atoms into chemical heat treatment process.

[carburizing]] : a method of solid cementite, liquid and gas carburizing carburizing, carburizing new technologies have vacuum carburizing and ion carburizing etc. Including raw gas carburizing process maturity, abundant resources, the most widely used.

Gas carburizing medium: there are two kinds, one kind is organic liquid hydrocarbons such as kerosene, methanol, Another kind is gas medium such as liquefied petroleum gas, natural gas. Carburizing medium or high drip into more than 900 degrees Celsius) (carburizing, make its decomposition furnace for active carbon atoms, reactive [C] are as follows: 2CO——CO2+[C] CH4——2H2+[C]

Gas carburizing: carburizing temperature is usually 900 ~ 950 degrees c, make steel completely austenite, workpiece surface by adsorption of carbon atoms into austenite and diffusion, access to certain youbiaojili carbonitriding layer thickness. The time to maintain the carburizing according to the requirement of depth, general per hour to finish 0.1 ~ 0.15 mm of depth. After carbrization general surface carbon quality score reaches 0.85% ~ 1.05% (n = 7), Carburizing layer depth from the surface to the general provisions within the mass fraction to carbon (generally for wc = 0.4%), the vertical distance of workpiece carburizing layer depth depends on the size of workpiece and working conditions, generally for 0.5 ~ 2.5 mm.

[carburizing steels] : a general use carbon quality score for 0.1% ~ 0.25% low carbon steel, low carbon steel or 20Cr 20CrMnTi, such as 20, etc. Can make carburized parts surface high hardness, wear, the heart of high-strength toughness, large impact.

[after carbrization heat treatment and performance] : after carbrization must be approved by the temperature quenching + after tempering can satisfy requirement of performance. After heat treatment in surface carburized parts to martensite and carbide organization, general surface hardness 64HRC - 58. But according to the heart of the size of its quench-hardening ability by steel parts size and low carbon, obtain martensitic or other organizations martensite heart of good tenacity.

[carburizing application] : mainly used in high hardness and high requirement surface resistance and good heart of plasticity and toughness, such as automobile parts of the sliding gears and machine gear, CAM shaft and piston pins, etc.

2 and nitrogen (n)

In certain - nitriding is medium temperature in certain that the nitrogen atoms into the workpiece surface chemistry of heat treatment process. The main methods gas nitriding and ion nitriding, etc.

[gas nitriding process] : the average temperature for nitriding 500 ~ 56 degrees Celsius, time is 30-50 hours, ammonia (NH3) nitriding medium. Ammonia in 45 degrees or above temperature, active nitrogen atoms decompose:2NH——3H2+2[N]

Active nitrogen atoms are workpiece surface, first formed after absorption of nitrogen in alpha Fe, when the crystallology nitrogen than alpha Fe, forming the solubility of Fe4N, Fe2N compounds (.). Nitrogen is formed with many alloying elements, such as dispersion of AlN CrN nitrides, Mo2N, etc., these alloys with high hardness and nitrides resistance, high corrosion resistance. Therefore, 38CrMoAlA containing Cr, Mo, such as Al alloy elements of steel is the most commonly used nitriding steel.

Because gas nitriding process cycle is long, so the rapid development of nitriding methods such as glow ion nitriding, halide catalytic nitrate, high-frequency induction heating nitriding, etc.

the characteristic nitriding

(1) nitriding surface hardness up (equivalent to 65HRC ~ 72HRC). And keep to 56-600 ° c and not decrease.

(2) after nitriding steel parts, without other heat treatment deformation of nitriding is very small.

(3) after nitriding has good corrosion resistance. This is because after nitriding surface density of nitrides film.

(4) gas nitriding time is very long, thin layer also nitriding (0.3 ~ 0.6 mm) for. For example 38CrMoAl steel piston compressor obtain 0.4 ~ 0.6 mm nitriding depth, gas nitriding thesoaking time 60h needs.

[application] : nitriding is suitable to wear the precision requirement surface parts. Such as grinder spindle, boring boring, precision machine tool bar, internal-combustion engine crankshaft and various precision gears and measuring etc.

Carburizing and nitriding process

Process temperature/c time/h follow-up treatment (HRC) surface hardness material deformation, for example

Gas carburizing 645-950 3 ~ 9 quenching temperature tempering 58 64HRC ~ + Cr, 20,20 big 20CrMnTi

Gas nitriding 500-600 20 ~ 50 need not 1200HV ~ 65-950 equivalent 72HRC small 38CrMoAl

nitrogen used parts of permeability, such as structure, worm gear axle parts, etc.

Four, nitrogen, carbon and nitrogen of permeability (soft)

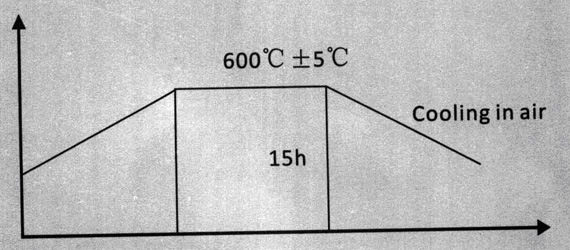

In the workpiece surface and infiltration with nitrogen and carbon, and the chemical treatment nitriding process called total nitrogen and carbon also called soft nitriding. The temperature of carbon nitrogen is generally 10 ° c ± 5.6, holding time is generally 3h ~ 4h, heat preservation can be released after the cold air. Total nitrogen gas seepage of carbon nitrogen, carbon and nitrogen and carbon of liquid of permeability and production more than two in total nitrogen gas permeability by carbon.

Nitrogen, carbon carbonitriding layer of surface hardness of slightly lower than nitriding, so called soft nitriding, but still has high hardness, wear resistance and high fatigue strength and corrosion resistance has obviously improved. The total nitrogen carbon heating temperature is low, the processing time is short, steel, and no small deformation by material limitation, so is mainly used for processing all kinds of work as well as some of the axial parts moulds.

Chemical treatment methods, in addition to the many ways, boriding and sulfur, metal seeping (such as seepage chromium, alumetizing etc), multi-elements (such as aluminum, nitrogen, and sulfur chromium carbon, nitrogen, carbon and nitrogen sulfur boron such).